Is manufacturing coming home?

Offshoring has been a popular strategy for many manufacturers for several years, with many businesses choosing to reduce operating expenses and create high-quality products at reduced rates outside of the UK.

Although this trend often gets bad press for its impact on local business and unemployment, it also reduces prices at home and can help emerging economies abroad. But with expanding overseas wage bills, unpredictable supply chains and increasing global instability, more businesses are looking at bringing their manufacturing back home.

With the growth in ‘just-in-time manufacturing’ and fast-moving markets, the industrial manufacturing powerhouse that is China has had difficulty in addressing these issues. Further disruption is being caused through rolling enforced blackouts to limit power consumption, effectively limiting the working week and reducing capacity. This is only likely to get worse as the pressure from the global focus on climate change restricts China’s ability to bring online more fossil fuel power stations. Combined with port restrictions in Tianjin and shipments being ‘bumped’ off vessels creating further shipping delays, it’s easy to see where local manufacturing becomes more attractive. Global players such as Apple and Go Pro that have already expanded local facilities and moved manufacturing closer to their key markets have seen the benefits of being able to exercise a more strategic manufacturing vision.

The bottom line

Cutting costs has always been the key driver for offshoring. But over recent years the direct costs of manufacture in Asia and other popular offshoring regions have steadily been increasing. It is not uncommon for workers to be demanding pay increases in excess of 30%, not just annually, but multiple times a year. The indirect costs, those associated with manufacturing added to the component and labour elements, have also been rising at a much faster pace. Many companies who have exploited workers and have had little time for health and safety are now having to respond to pressure from consumers and embrace more environmental and worker rights legislation, which directly impacts margins and increases costs.

So, with all this going on, what are the benefits of onshoring your manufacture to the right local partner:

- Logistics becomes simpler for the finished goods; it is unlikely to get stuck in the Suez Canal holding up your inventory for months whilst insurance companies argue.

- Forecasting your requirements will be simpler and can be more responsive to changes; you would not need to factor in six weeks at sea which directly impacts the value of the inventory you need to secure ahead of time.

- Ease of introduction of new products and responsiveness in your time zone makes supply chains and inventory levels more predictable.

- Quality can be more simply managed without the need for third-party inspections and auditing or permanent staff at the factory. The UK has a long and well-deserved reputation for quality, with globally recognised systems and quality standards.

- Manufacturing is more sustainable. According to the WWF conservation charity, around half of the UK’s real carbon footprint is accounted for with international travel and associated with the manufacture of goods made overseas but imported to the UK. Manufacturing local to your market will positively contribute to countries achieving carbon net-zero targets sooner.

It’s okay to embrace local

Many UK based manufacturers are responsive, can provide excellent quality and when you consider the Total Cost of Manufacture beyond just the ex-works ‘Cost of Goods’, can also be competitive. The UK in 2020 was the ninth largest manufacturing nation by output and has continued to grow despite of the considerable external threats. Electronic manufacturing in the UK can compete through the implementation of automation and the adoption of digital technologies. Gartner surveyed Supply Chain leaders last year and indicated that a third of them were moving at least some of their manufacturing before 2023. With recent shortages and struggles to supply, you can reasonably infer that number will be even greater this year. And while we have always liked to promote the idea of buying British, consumers are increasingly looking for products made in their own country. Working with local partners supports the economy and lets businesses take pride in producing quality, British-made products.

What can you do? At Plextek we can help you review third-party supply chains, identify risks and suggest ways to mitigate them. In addition, we can help with the moving process, making sure the right local party is selected and capable of supporting your requirements and strategy going forward. With detailed scrutiny of your manufacturing, we can help provide you with a holistically beneficial cost foundation for your production.

It may not be for everybody, but now is the time to seriously consider manufacturing coming home.

Technology Platforms

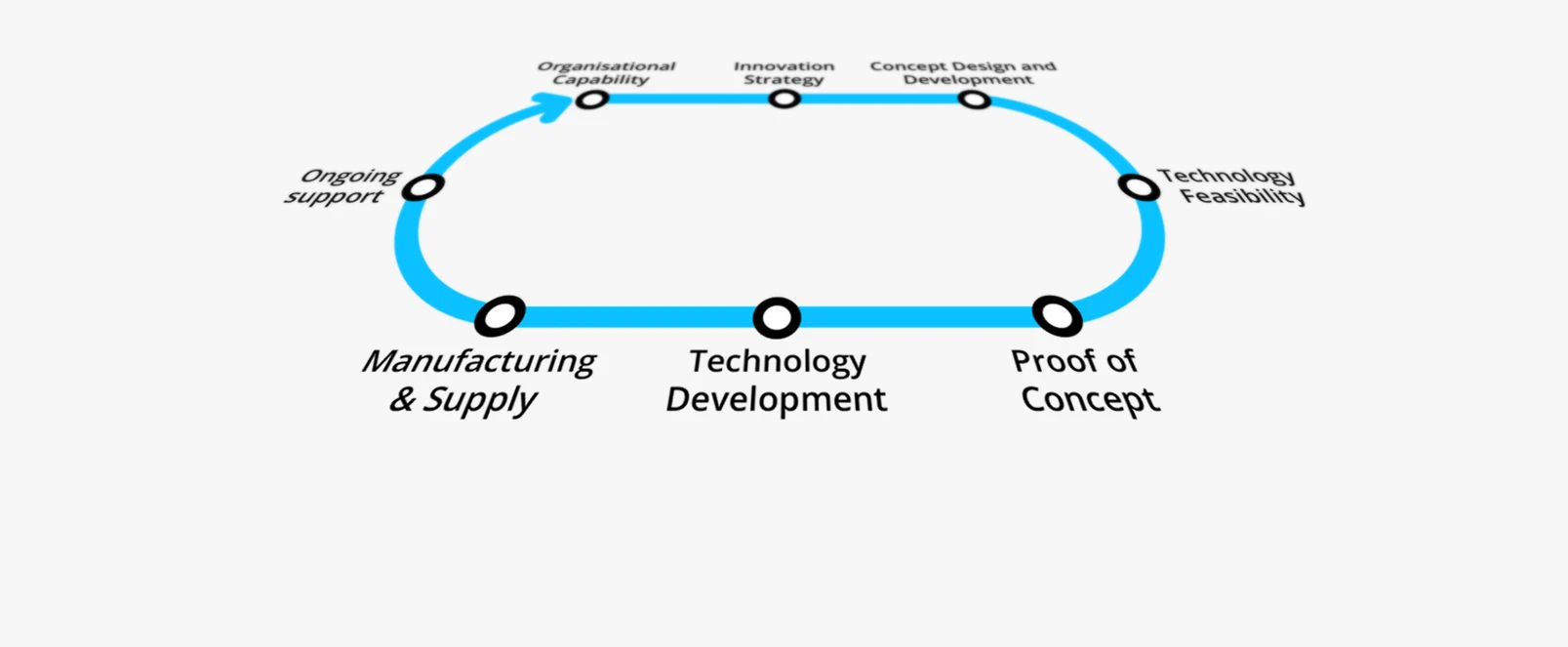

Plextek's 'white-label' technology platforms allow you to accelerate product development, streamline efficiencies, and access our extensive R&D expertise to suit your project needs.

-

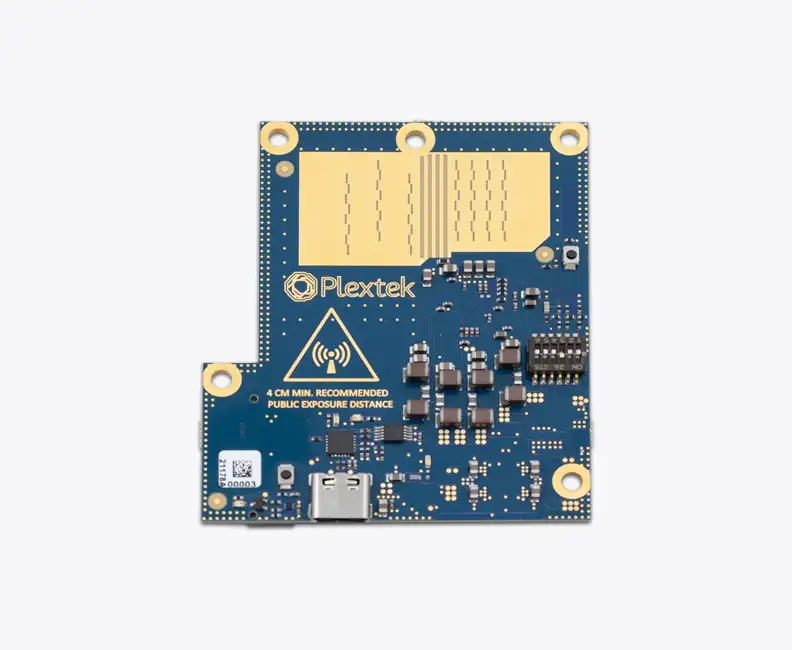

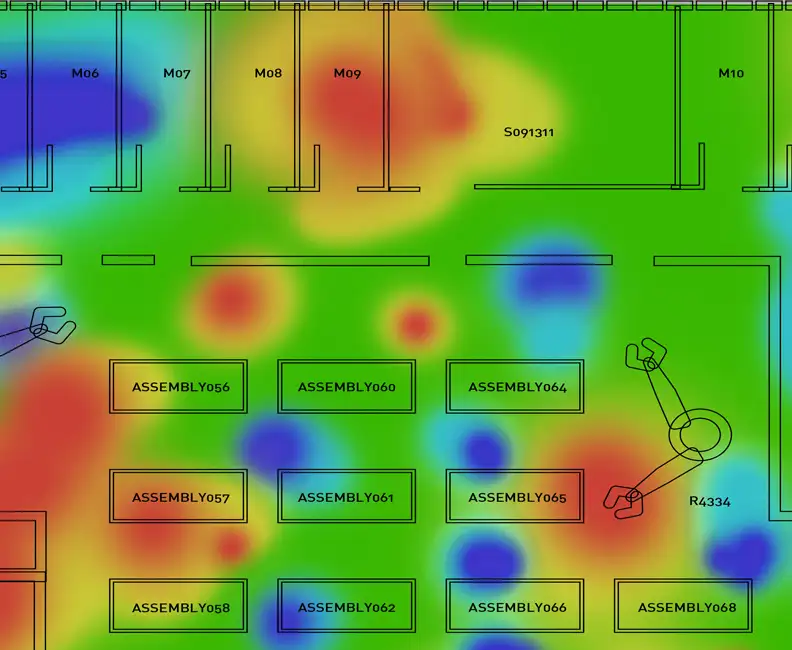

01 Configurable mmWave Radar ModuleConfigurable mmWave Radar Module

Plextek’s PLX-T60 platform enables rapid development and deployment of custom mmWave radar solutions at scale and pace

-

02 Configurable IoT FrameworkConfigurable IoT Framework

Plextek’s IoT framework enables rapid development and deployment of custom IoT solutions, particularly those requiring extended operation on battery power

-

03 Ubiquitous RadarUbiquitous Radar

Plextek's Ubiquitous Radar will detect returns from many directions simultaneously and accurately, differentiating between drones and birds, and even determining the size and type of drone