Condition Monitoring

Accurate real-time detection of even the subtlest changes in machinery operation

Condition monitoring provides a vital early warning sign of potential problems whether this be with a production line, or a single machine, or a critical piece of infrastructure – picking up even the most subtle changes before a human could detect that something might be going wrong.

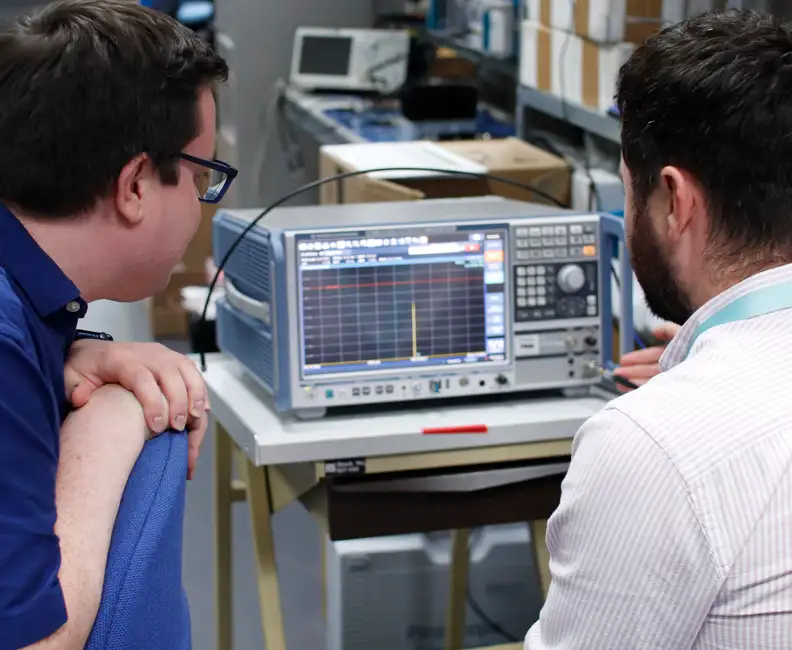

Parameters such as vibration, acoustics, temperature and humidity, to name but a few, can all be monitored in real time using Internet of Things (IoT) sensors attached to machines at key points of a production line, for example, or a remote piece of capital equipment or some critical hardware.

The aim is to detect any deviation from normal operation that might suggest maintenance or safety measures are required, with the data either streamed for real-time analysis, logged for regular reviews or automatically processed to generate alerts.

This kind of predictive maintenance can save time and money – cutting out unnecessary routine work and focusing efforts on the crucial maintenance that is required to address specific potential issues long before everything grinds to a halt. It also improves safety – detecting potential hazards early, or even predicting them in advance to prevent them from developing.

Real-world challenges

Key skills

-

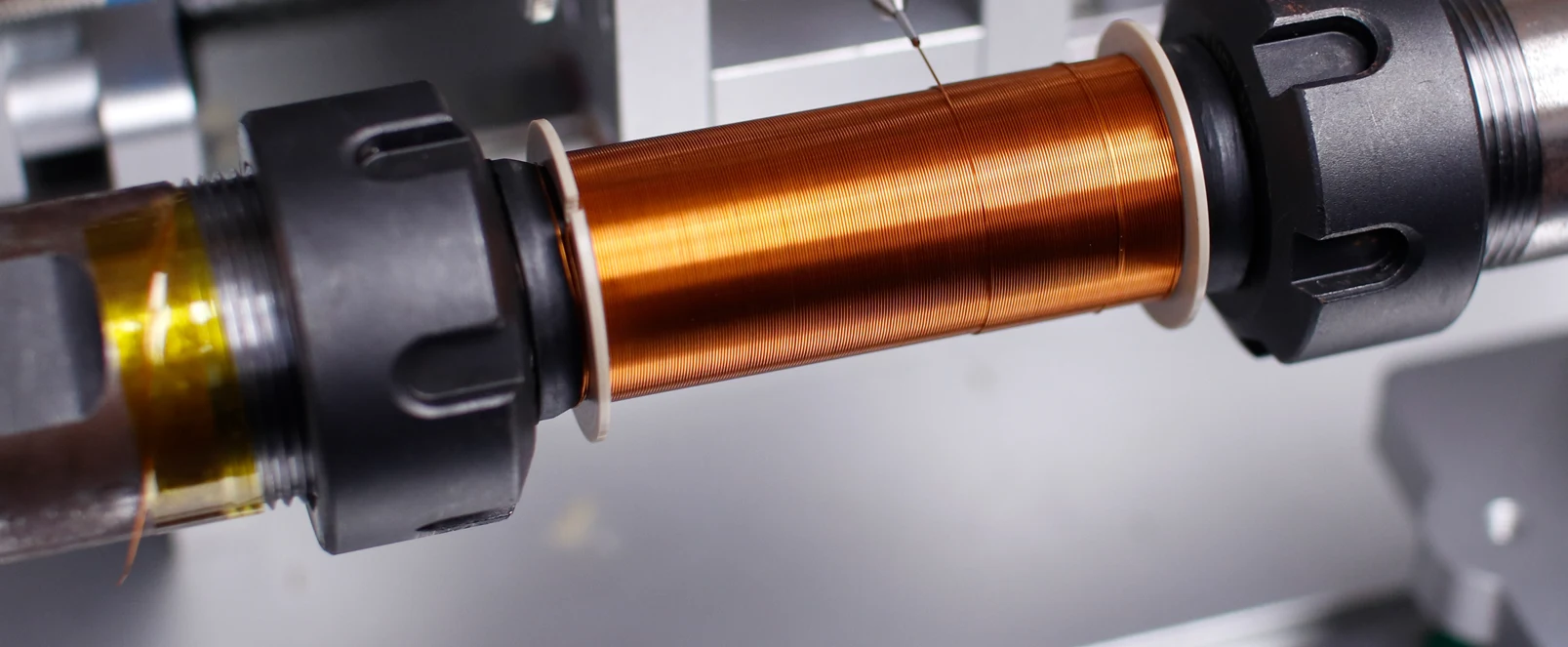

Sensor physics

It is important to choose appropriate sensors to measure relevant parameters.

-

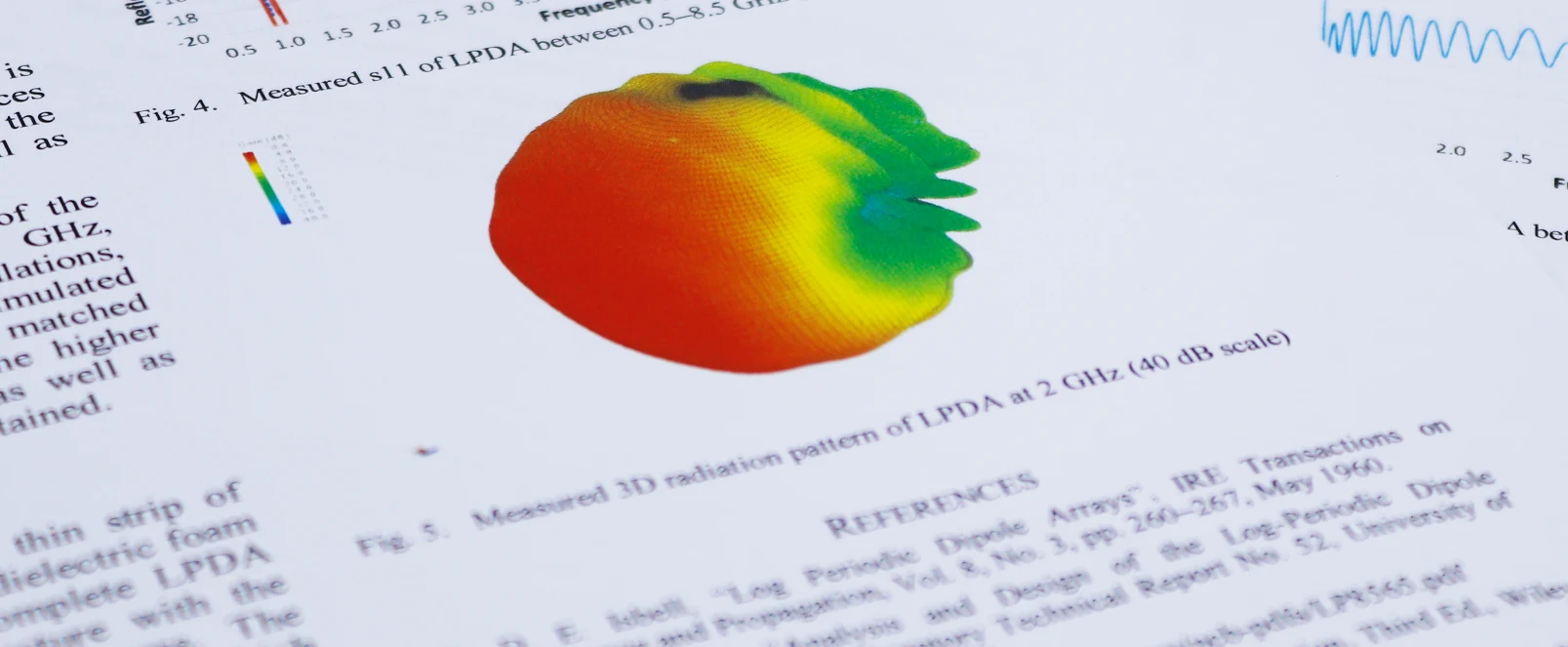

Time-frequency analysis

Many failure modes produce a change in frequency of a periodic signal that varies as the condition worsens.

-

Machine Learning (ML)

Using measured data, algorithms can learn to detect and classify anomalous operation.

-

Edge analytics

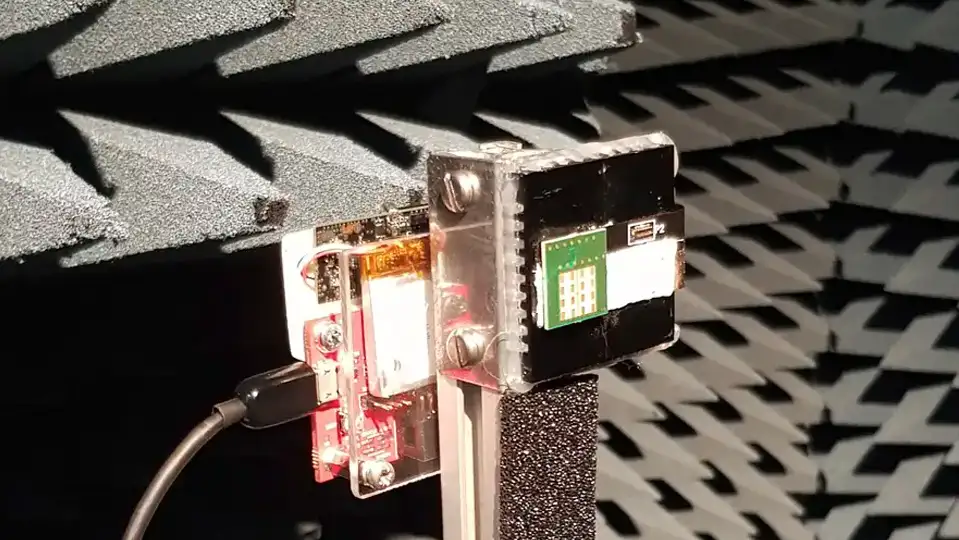

Real-time analysis is often best performed on the sensor device itself rather than at a central server.

-

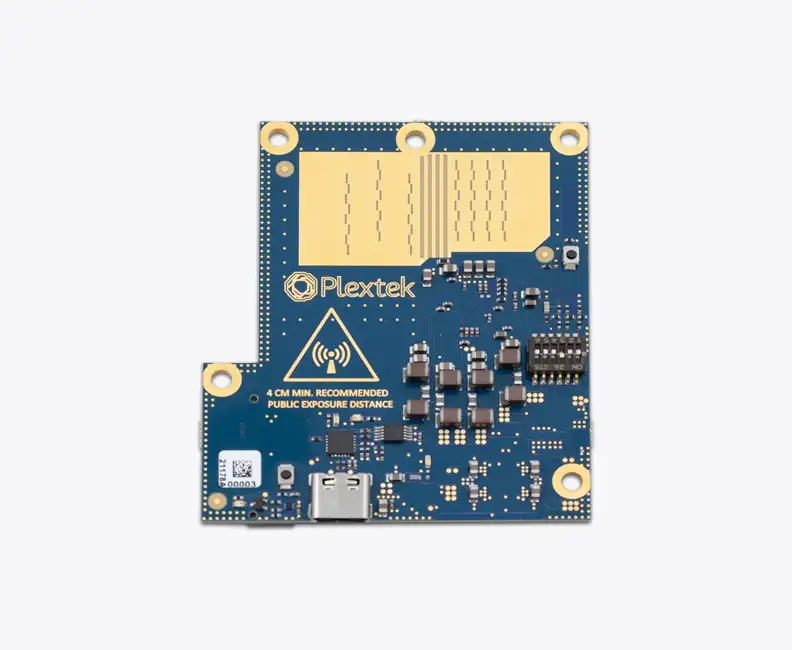

Low size weight and power electronic systems design

Many condition monitoring systems must be small and last on battery power for extended periods.

What sets us apart when it comes to condition monitoring?

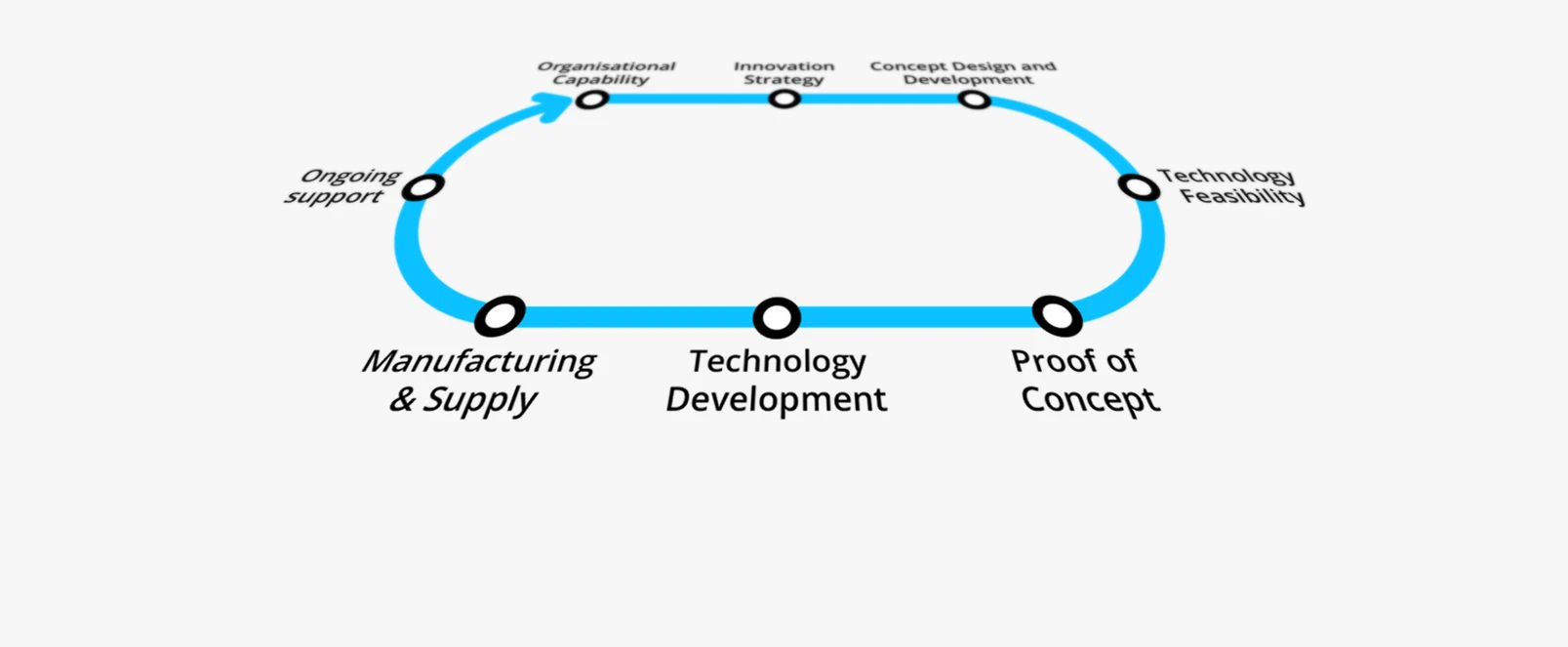

Developing a condition monitoring system from initial idea to a final deployed product can involve many steps. Plextek is well positioned to perform any – or all – of these steps, depending on the client’s needs:

- Concept generation

- Sensor selection

- Preliminary data gathering

- Wireless communication

- Database management

- Algorithm development

- Live system testing

- Custom hardware design

- Manufacturing

- Predictive maintenance