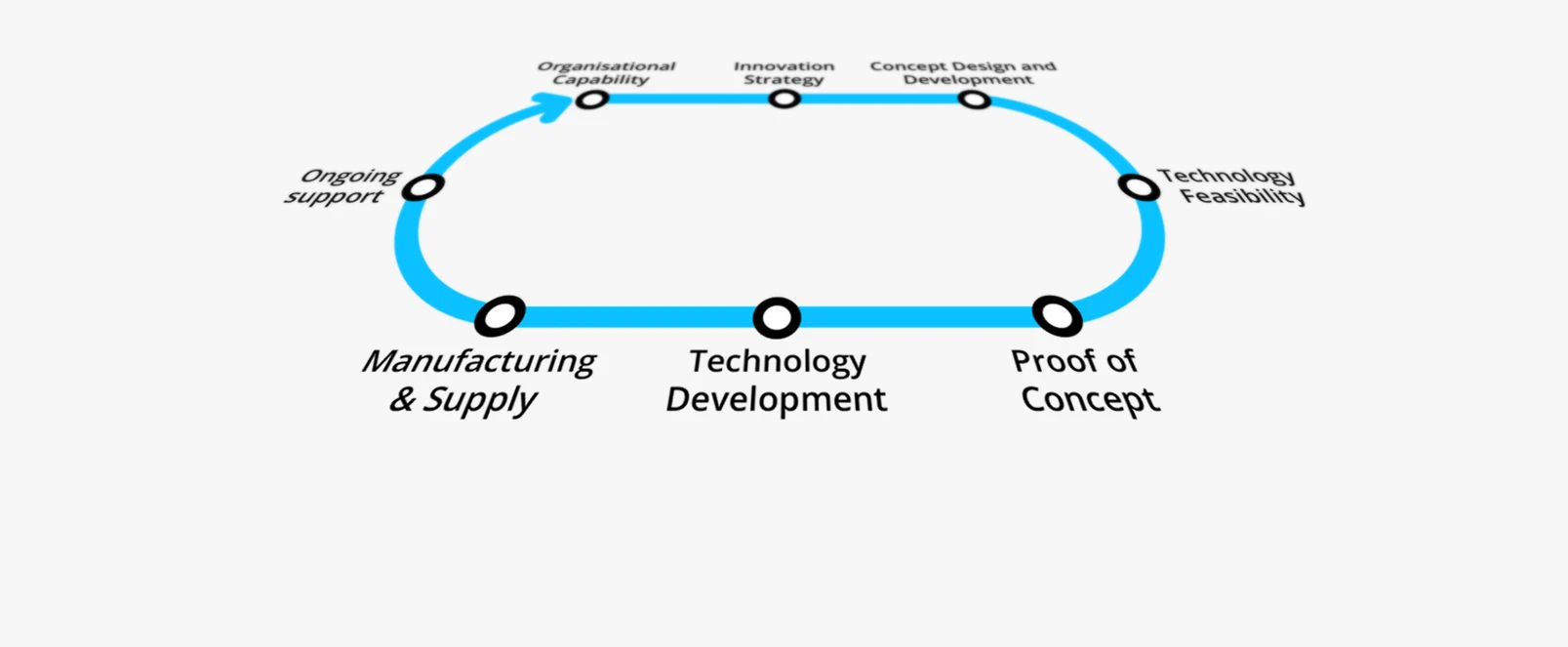

Rapid Proof of Concept

Reducing risks and costs while speeding up product development

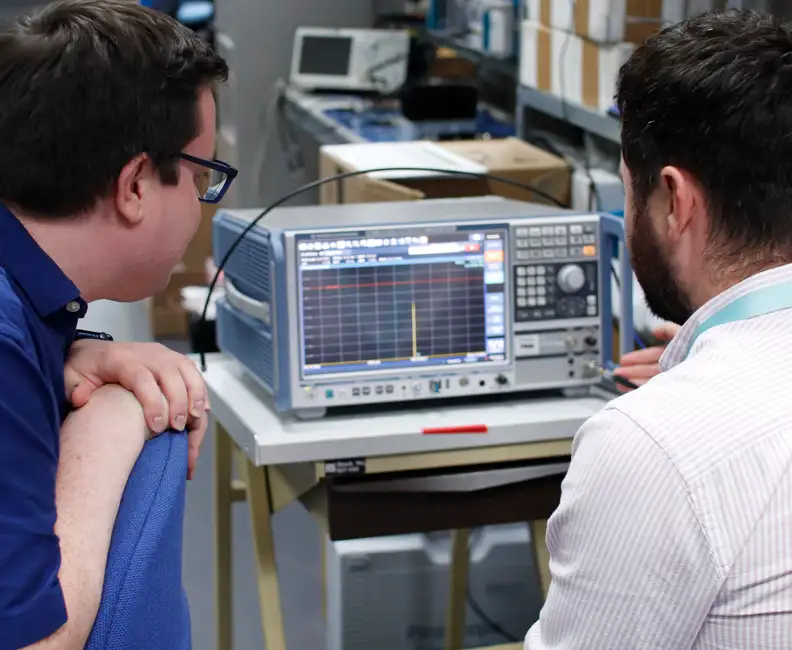

The first prototype is a crucial step in any design – testing the functions of a product and revealing any pitfalls in the design at an early stage.

That’s why rapid proof of concept is crucial, as it reduces the risks associated with new products, reduces development costs and speeds up the development cycle.

To get to the first prototype quickly, with minimal investment, the manufacturing processes used are often different from high-volume production ones. Off-the-shelf components might be used and modified, for example, metal components are often machined instead of cast, and plastic components are often 3D printed, instead of moulded.

With 3D printing, some elements of a design can even be tested before a prototype is assembled. A plastic version of an aluminium heat sink, for example, can be printed off in just a few hours – ahead of production – to make sure it fits together with the other parts of the assembly in the way expected.

Real-world challenges

Key skills

-

3D printing

Using selective laser sintering (SLS) technology to create precise prototypes. This allows rapid testing and refinement of designs.

-

CAD modelling

Expertise in leveraging CAD tools for designing and analysing heat dissipation across product systems, which is crucial for functional prototypes.

-

Mechanical design

Using Creo software for comprehensive mechanical engineering and design solutions.

-

Prototype assembly

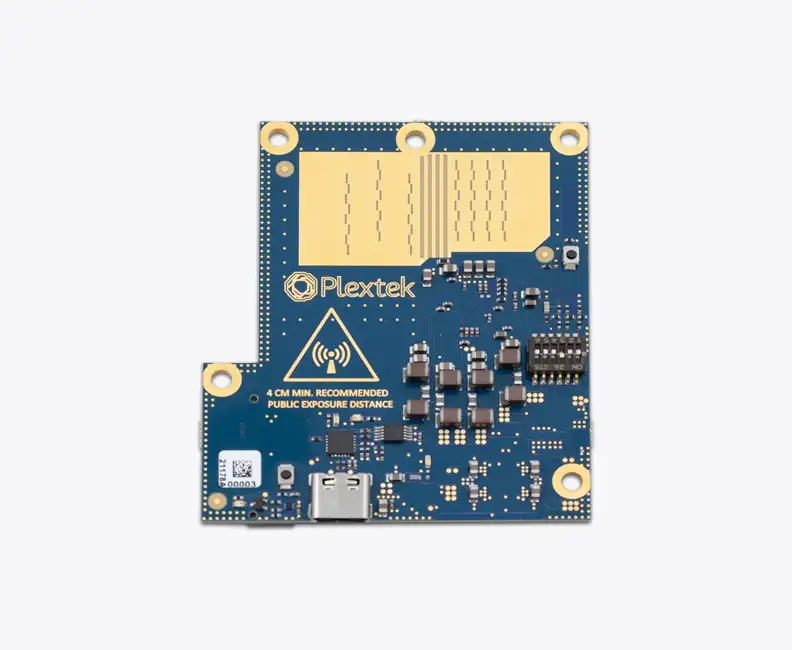

With technicians proficient in PCB assembly and general prototype construction, certified to ISO610 Class 3 standards for soldering and inspection.

-

PCB CAD design

Using advanced PCB layout software, including Altium or PADS, coupled with local fabrication partnerships, to develop and produce complex circuit designs efficiently.

-

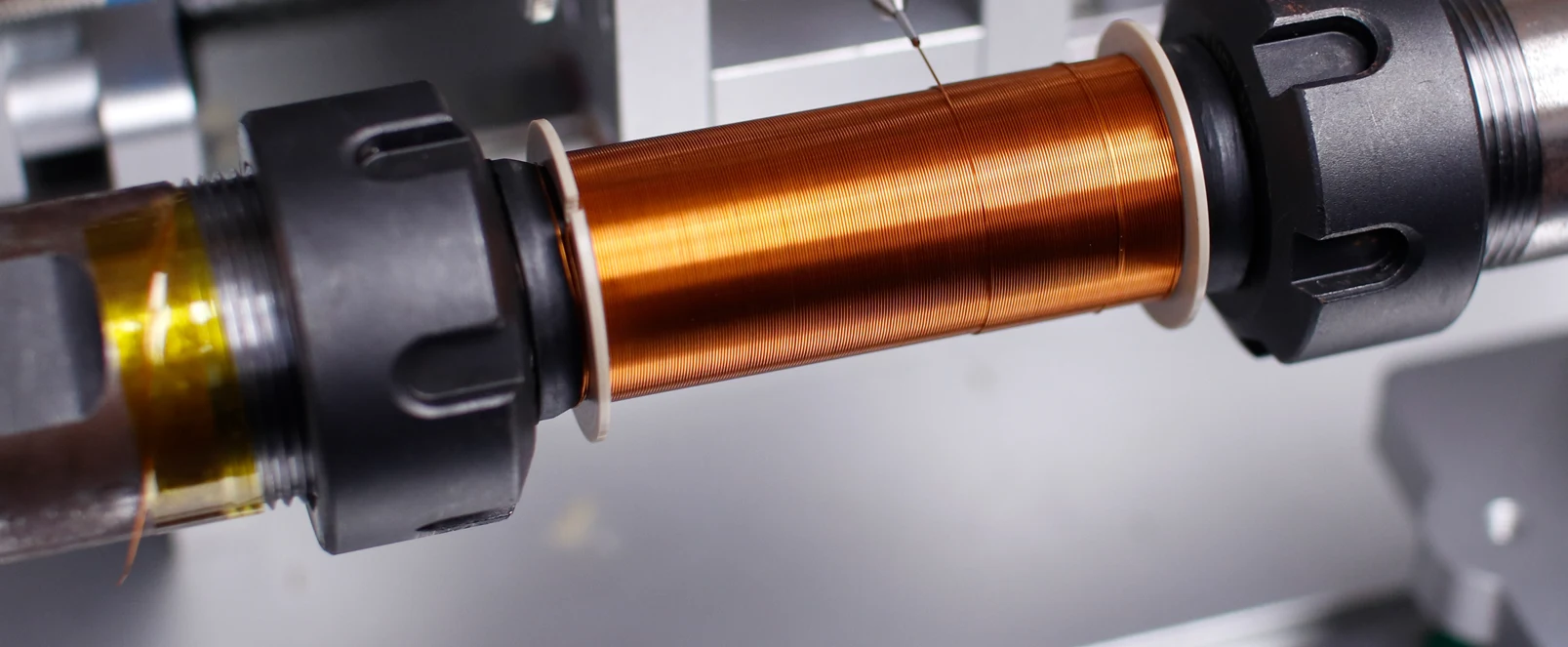

Additive manufacturing

Additive manufacturing technologies enable fast transformation of digital models into physical prototypes.

What sets us apart when it comes to rapid proof of concept?

Our experienced manufacturing and technical teams bring client ideas to life through prototypes – ensuring each concept is validated and prepared for the next development stage.

Our fully equipped workshop transforms CAD designs into real working samples, with facilities including:

- SMT assembly

- Comprehensive mechanical workshop

- Advanced 3D printing technologies (SLS and FDM)

- Creo CAD software for detailed designs

- Latest in PCB layout software (PADS and Altium)

The services we offer to clients include:

- 3D printing solutions

- Additive manufacturing techniques

- CAD modelling for heat dissipation

- ISO610 Class 3 soldering

- Mechanical design with Creo

- PCB assembly and prototyping

- PCB CAD design fabrication

- Prototype manufacturing and assembly

- Rapid prototyping services