Technical Services

Delivering rapid, cost-effective product development optimised for manufacturing

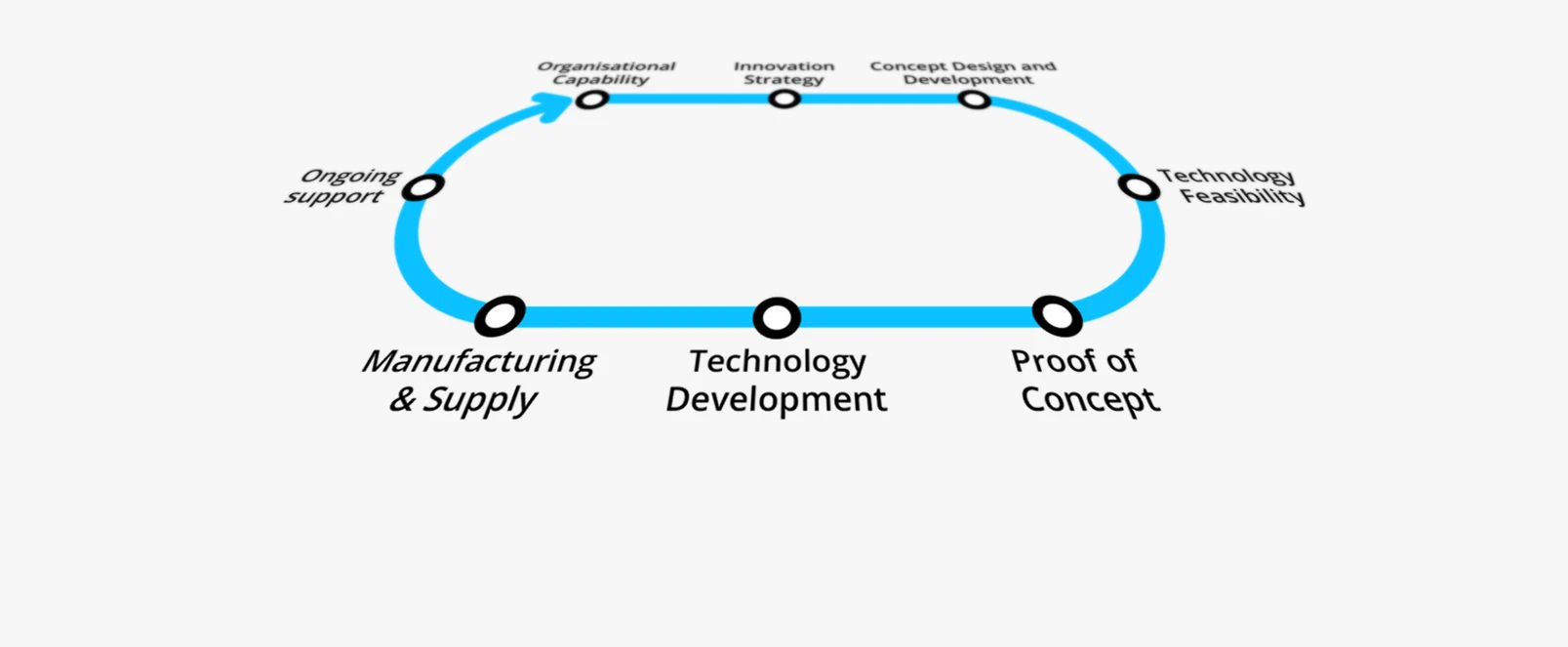

Technical services is an umbrella term for a whole range of activities designed to deliver rapid, cost-effective product development optimised for the production line.

From buying materials and organising documentation to prototyping and ensuring products conform to a specific build standard, the emphasis is on managing a product into low-volume or mass production.

The secret of success is risk assessment to understand what actions need to be taken to keep a project on schedule – specifying the parts that will be needed, for example, and making sure they can all be obtained in time.

An extensive network of supplier relationships helps with sourcing components at short notice for rapid assembly of prototypes, while in-house expertise enables custom parts to be fabricated and assembled to meet deadlines and cost requirements

Real-world challenges

Key skills

-

Prototype service

Either in-house or using local sources, creating electronic/mechanical samples before expensive tooling needs to be started.

-

3D printing

As part of prototyping, we have a selective laser sintering (SLS) 3D printer (159mm x159mm x295mm model size).

-

CAD modelling

Expertise to analyse heat dissipation in a fully functional product system.

-

Mechanical design

Using the latest Creo design software.

-

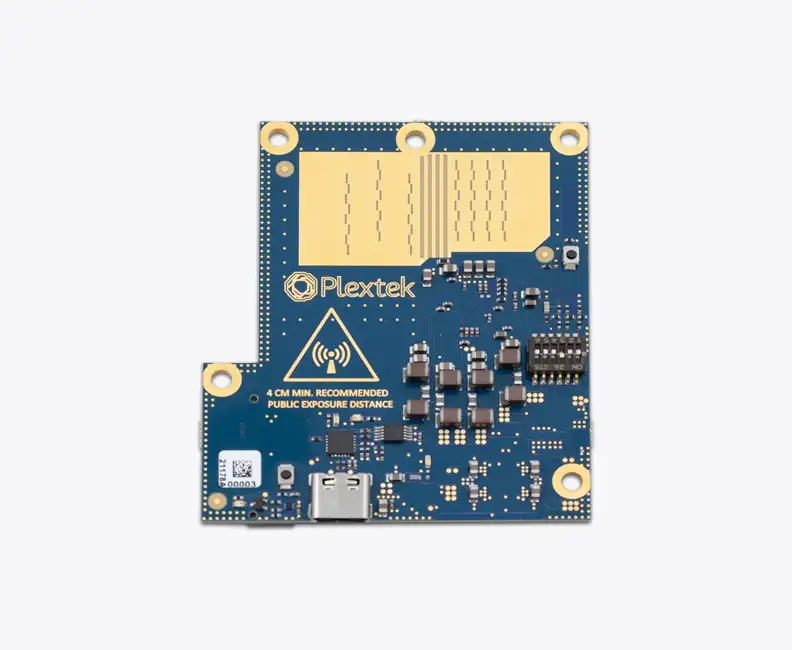

Siemens PADS or Altium Designer PCB layout

Extensive expertise in the design of RF, analogue and digital high-speed PCB layouts for rigid, rigid-flex and flexible circuits.

-

New product introduction (NPI) and design for excellence (DFx)

Management of all aspects of product development from a manufacturing point of view. Creation of a timeline structure for just a few prototypes or stepping stones to full production.

-

Supply chain management

Advising on the choice of best contract manufacturing services and customised part manufacturing vendors to match the business model and create the best partnerships for the future. Complete bill of material (BoM) analysis to avoid using parts close to obsolescence, prevent critical part shortages and understand the lead time ready for builds.

-

Design for factory product test

Developing test solutions which best match the business model with the capabilities for delivering a complete solution either to a client or to a contract manufacturer.

What sets us apart when it comes to technical services?

The Plextek manufacturing team has extensive experience in delivering products to support new technologies and growth markets such as radars, sensors and space. Our work includes:

- 3D printing

- Altium Designer

- BoM analysis

- CAD modelling

- Creo

- Custom manufacturing

- Design for manufacturing

- Manufacturing prototype timelines

- Mechanical design

- NPI

- PCB layout

- Product development management

- Prototype service

- SLS

- Supply chain management