Mechanical Design

Ensuring robust, efficient, and reliable products and systems

Mechanical design has a crucial role to play in everything from consumer electronics to automotive and aerospace applications – anything that involves components and systems that interact.

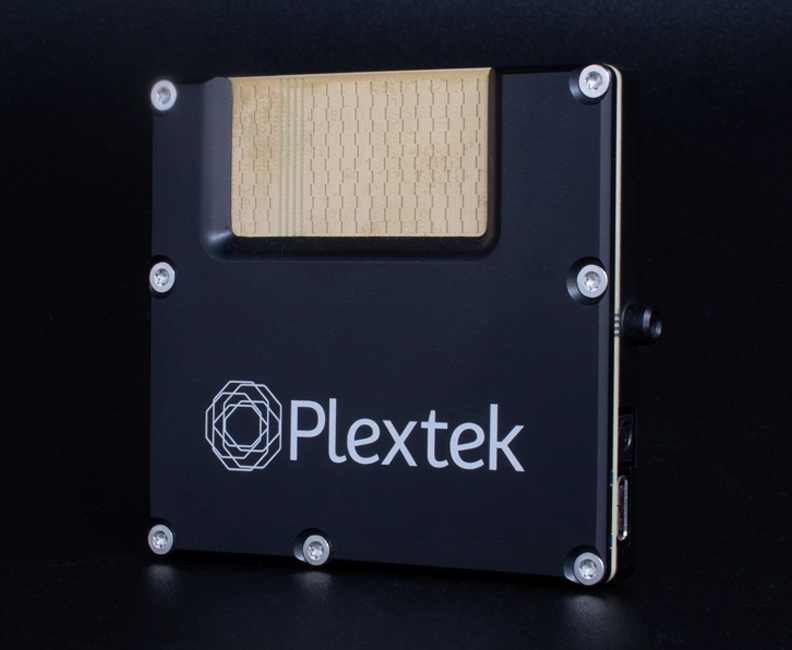

Its focus is on ensuring products have a winning combination of aesthetic, ergonomic and functional attributes whilst meeting manufacturing, assembly and quality assurance standards. Heat management and environmental protection considerations, such as waterproofing, robustness, and corrosion resistance must also be addressed.

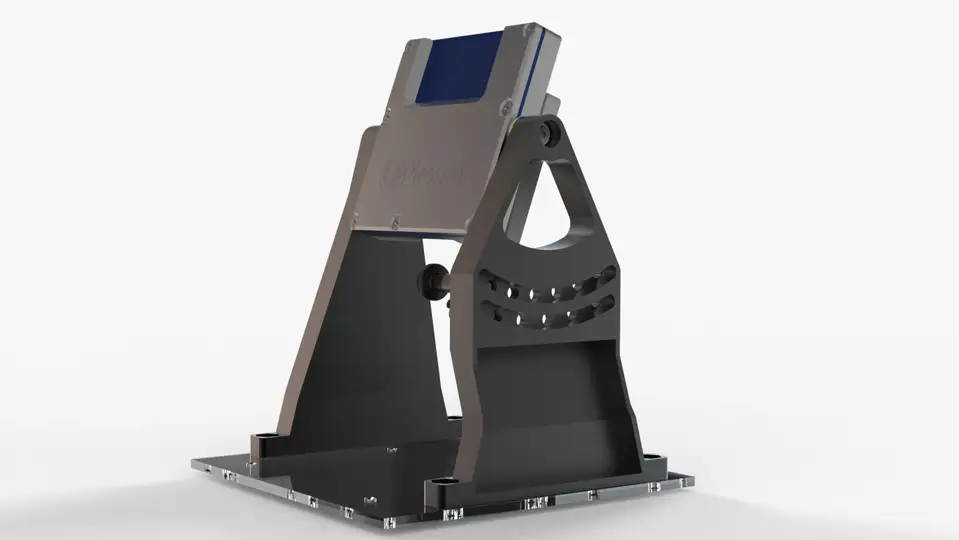

Advanced computational tools, such as 3D computer-aided design (CAD) software, make it possible to create detailed and precise models of mechanical parts, assemblies and the integration of mechanical systems with electronics, batteries and motor mechanisms. Modern generative Artificial Intelligence (AI) tools are also emerging which attempt to optimise mechanical design given various constraints and objectives, leading to new innovative designs that challenge traditional mechanical design approaches.

Mechanical design is also at the forefront of minimising the carbon footprint of industries and products – ensuring that the mechanical design supports an eco-friendly manufacturing process using sustainable materials.

Real-world challenges

The Plextek advantage

- Advanced CAD capability

Managing even complex geometry across component parts and assemblies to quickly evolve with project requirements.

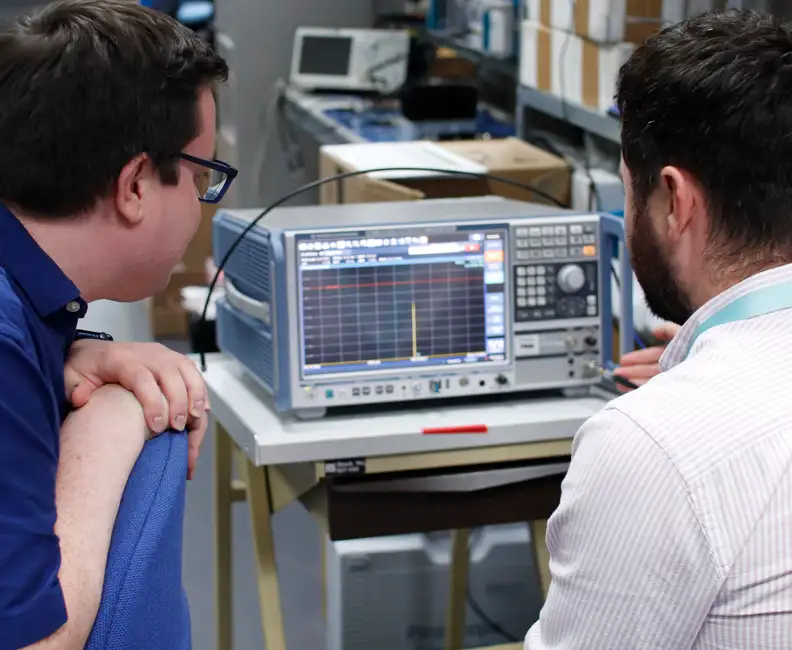

- Design verification and validation

Efficient design workflows rely on simulations, so we use finite element analysis (FEA) and prototyping to scrutinise and refine designs.

- Manufacturing expertise

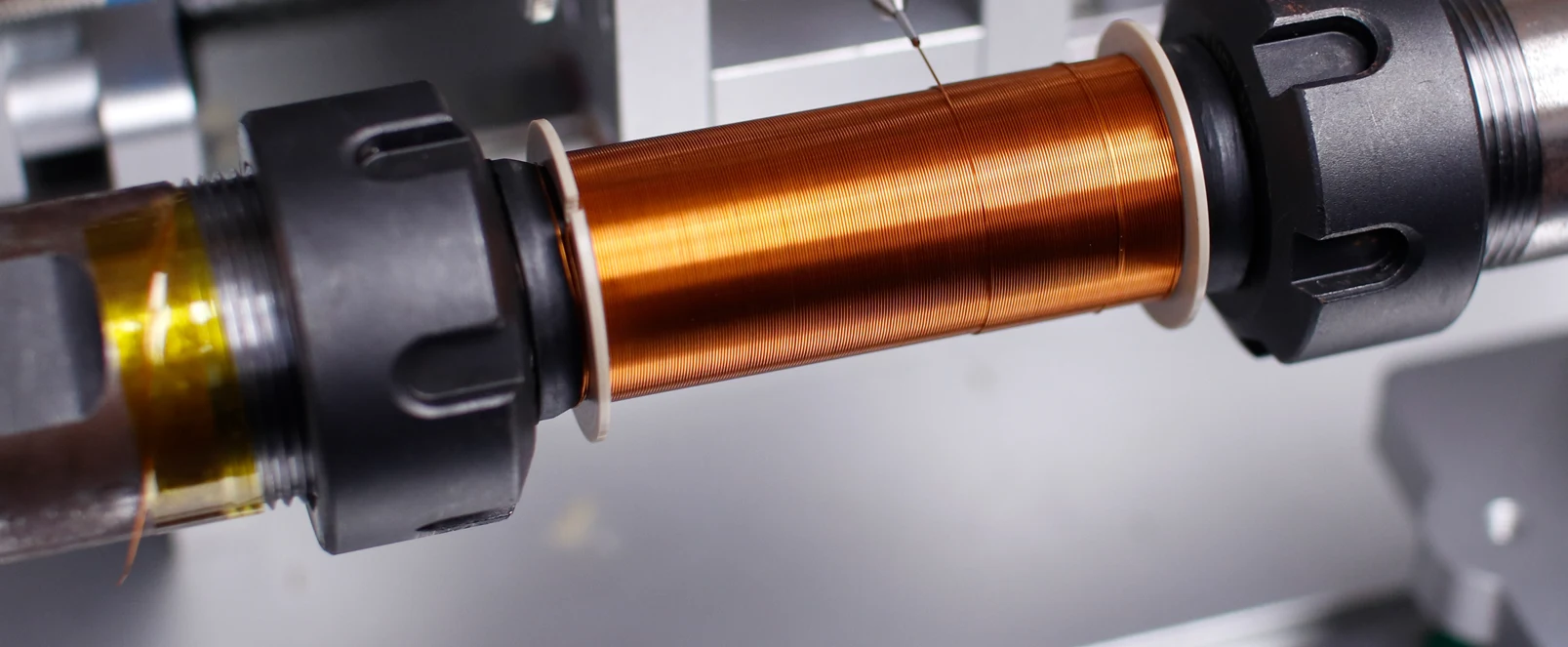

Using a range of manufacturing processes, employing in-depth knowledge of machining, sheet metal and welding, injection moulding, and a range of coatings and treatments.

- Material and finish selection

Choosing the best combination for an application from key performance criteria.

- Quality assurance

Starting early in the design process and continuing across technical drawings, fabrication and inspection using geometric dimensioning and tolerancing (GD&T) methodology.

- Collaboration

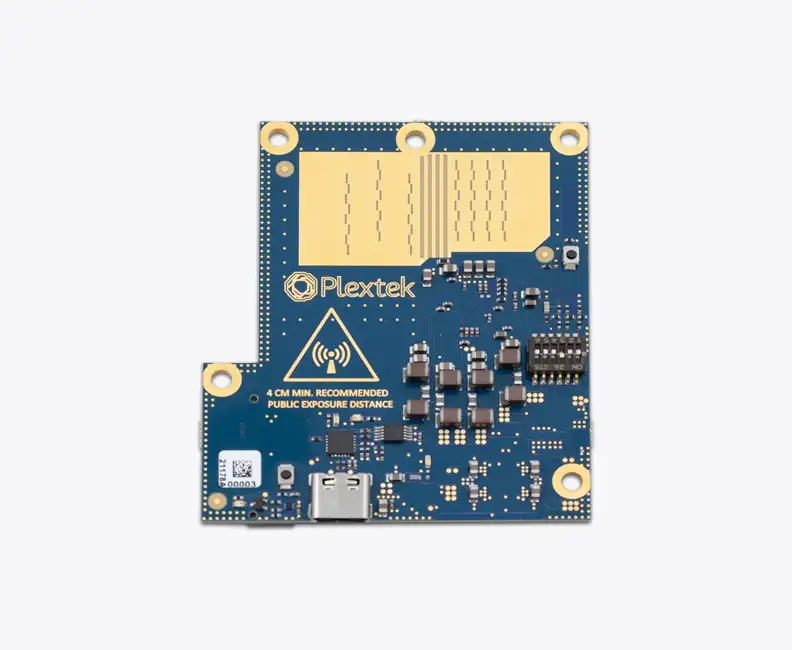

Seamlessly working with electrical and radio frequency (RF) engineers and capturing input from wider teams to ensure end-user expectations are fulfilled.

- Innovation

Doesn’t need to come at high cost as we combine our mechanical experience with a deep-dive analysis into the root cause of a problem to capitalise on fresh opportunities.

- Design optimisation

An analytical approach is crucial for both existing and new products, so cost, mass or other performance criteria are scrutinised and reverse engineered.

- Thermal analysis

Small, power-hungry products demand more thermal consideration, so we complement our experience in heatsink design with artificial intelligence (AI)-assisted tools to generate bespoke heatsink solutions.

- Product lifecycle management (PLM) and communication

Sharing ideas effectively is a crucial skill, so we complement our fast-moving design process from inception to end of life with detailed supporting documentation.

- Generative AI

Joint optimisation of mechanical design against conflicting requirements and constraints to yield novel and innovative designs.

What sets us apart when it comes to mechanical design?

Our extensive project delivery portfolio gives us a wide range of experience in areas including:

- Eco-friendly system design

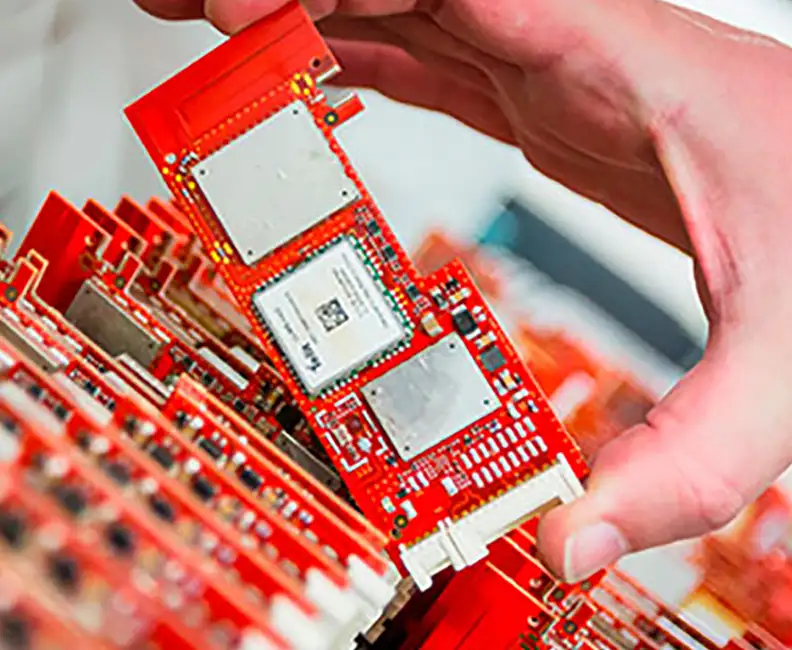

- Mechanical-electrical system integration

- Minimising carbon footprint through design

- Product aesthetics, ergonomics and functionality

- Prototype builds and testing

- Quality assurance

- Renewable energy in mechanical design

- Design for manufacture (DFM)

- Design for assembly (DFA)

- Design for inspection (DFI)

- GD&T

- CAD

- Computer-aided engineering (CAE)

- Computer-aided manufacture (CAM)

- FEA

- Anthropometric-driven design

- Reverse engineering

- IP Rating (ingress protection) to IEC 60529

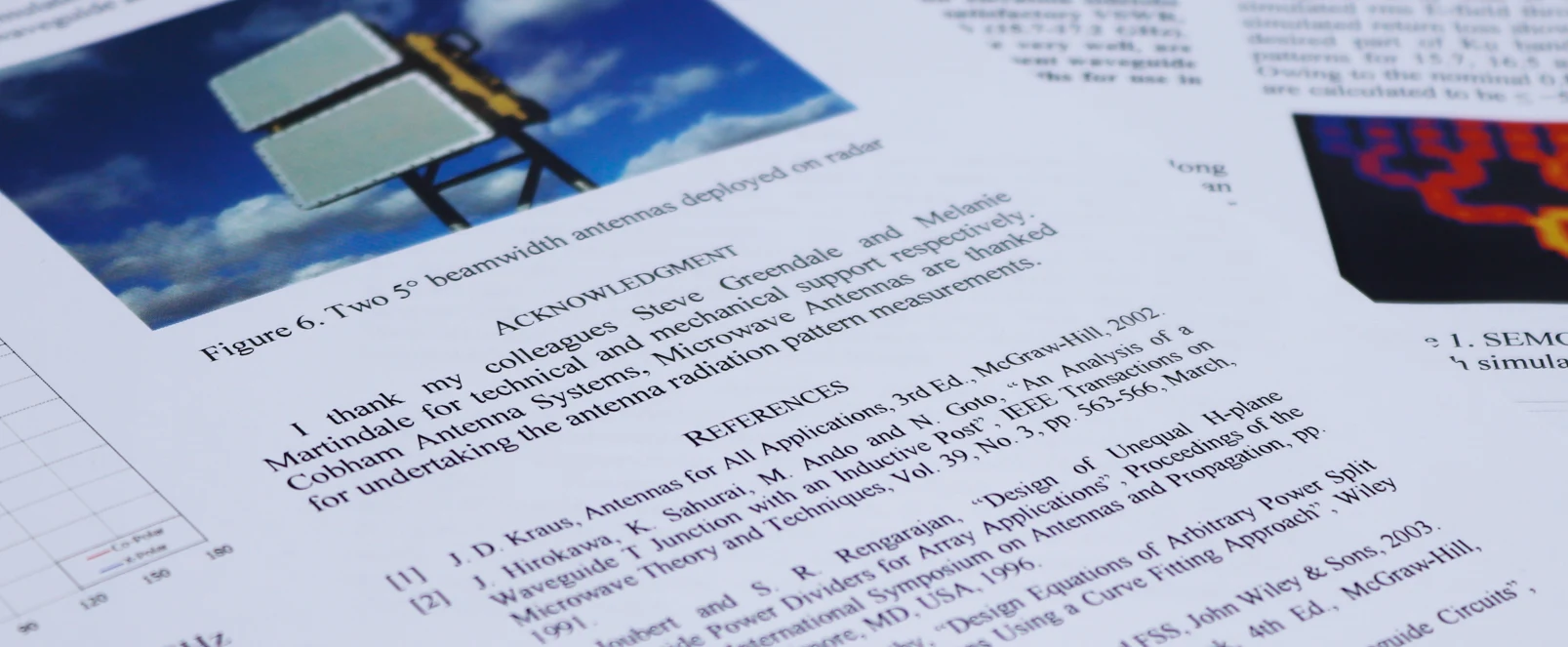

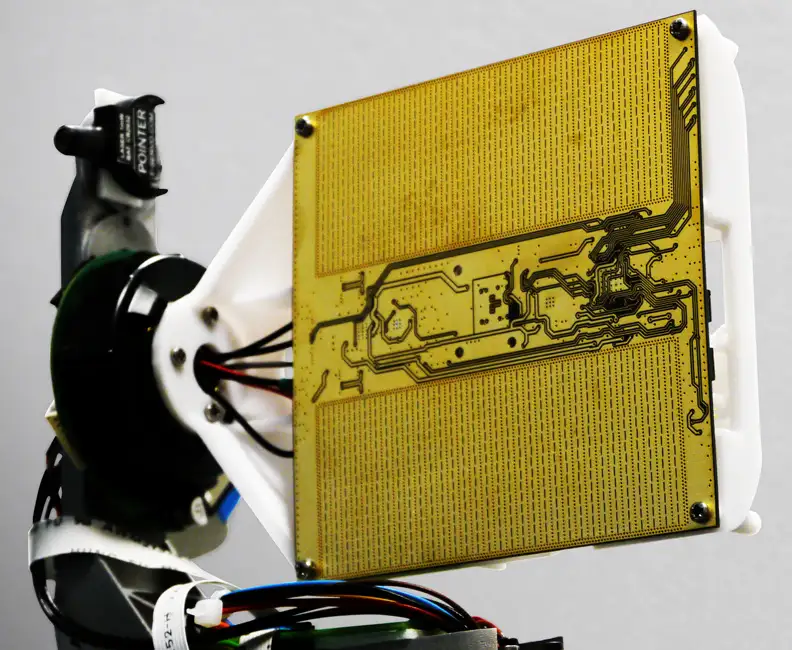

- RF waveguide design and linear polarisation

- Optical and cosmetic consideration

- Creo Advanced Assembly Extension (AAX)

- Design for Space

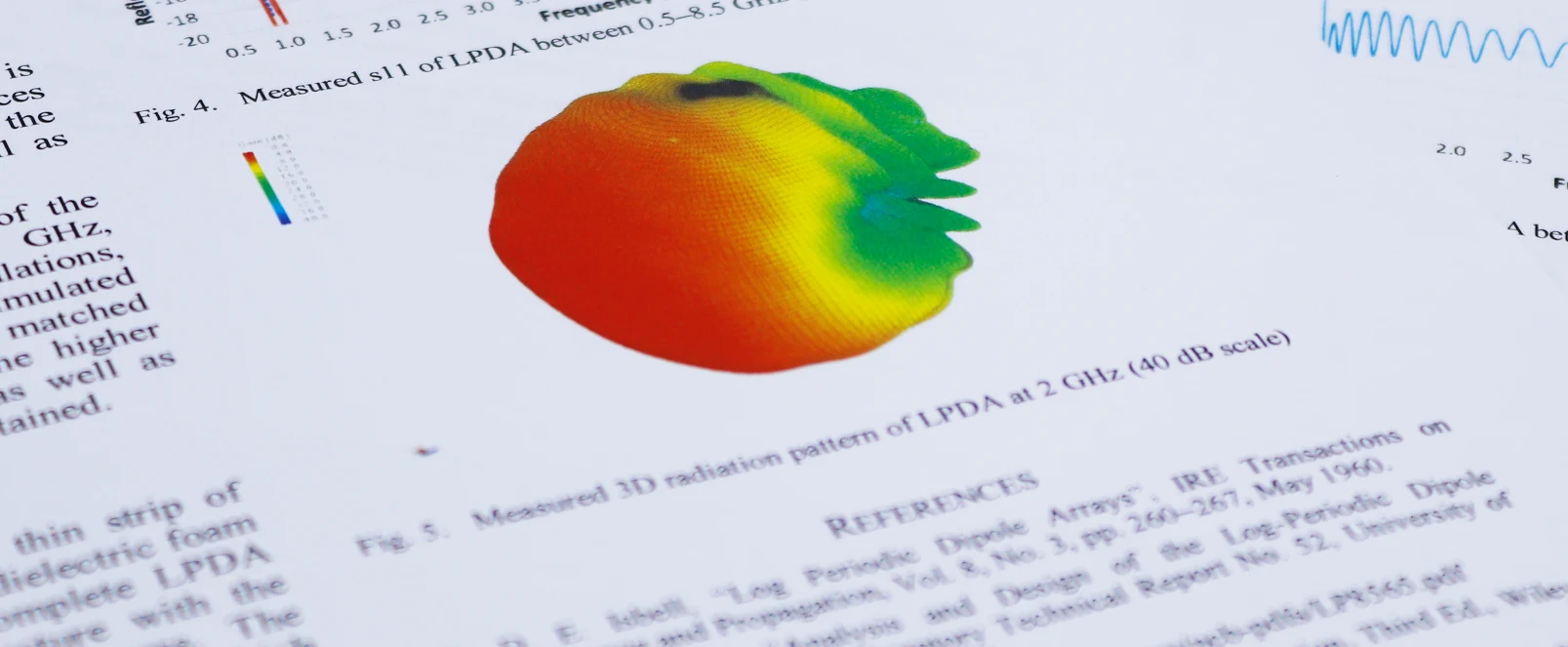

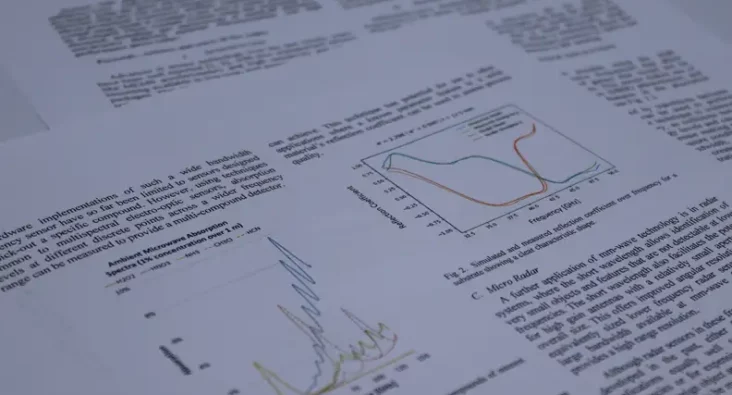

Related Technical Papers

View AllDownloads

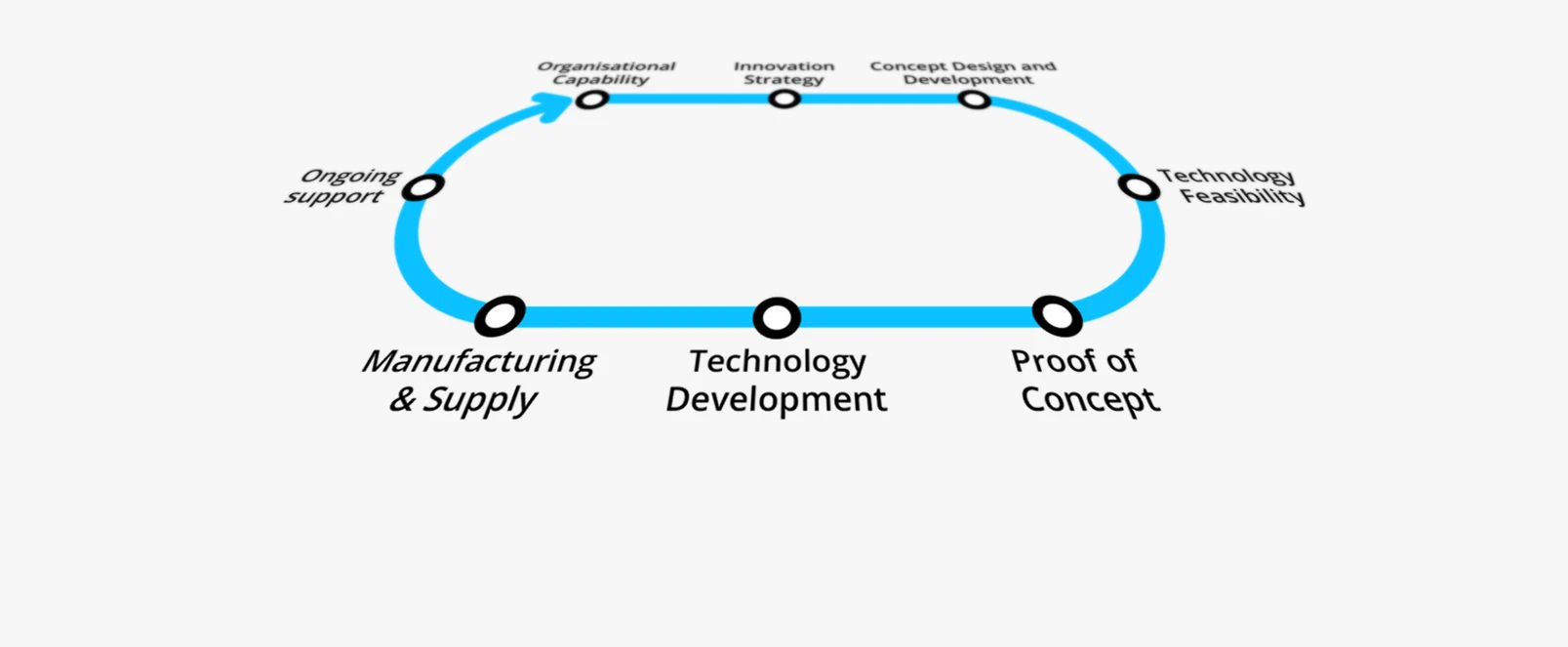

View All Downloads- Intro to Plextek

- Plextek – Your complete end-to-end solution

- PLX-T60 Configurable mmWave Radar Module

- PLX-U16 Ubiquitous Radar

- Configurable IOT Framework

- mmWave Imaging Radar

- Using 3D Printing to Optimise Product Development

- Low Cost Millimeter Wave Radio frequency Sensors

- MISPEC

- Cost Effective mmWave Radar Devices

- Connected Autonomous Mobility

- Antenna Design Services